Links to more pages on Metal Detectors:

http://www.next.gr/sens-detectors/metal-detector-circuits/

The Fundamentals of Electronic Prospecting - a discussion on

different types and their capabilities

http://www.goldgold.com/the-fundamentals-of-electronic-prospecting.html

Geotech: Lots of circuits of well-known metal (gold)

detectors:

http://www.geotech1.com/cgi-bin/pages/common/index.pl?page=metdet&file=schematics.dat

Remember this: almost all circuits (up to about 4 - 6 transistors) have the

same capability: detecting a 20mm coin at about 100mm. It doesn't matter if the

circuit is simple or complex, The sensitivity revolves around the circuit

driving the coil. Some circuits are more sensitive to "interference" and we have

demonstrated this in Circuits 1 - 8 at the end of the page. The

most-sensitive circuit is a 100mm dia coil with just 12 to 20 turns and operates at about

200kHz as shown in circuit 8. The frequency of the circuit will change by one Hertz and this can be

detected on an AM radio. You cannot get better than this.

The simplest circuit is shown below:

Another Simple Metal Detector Circuit

To learn more about the

basics of circuit-design and recognise components, component-values, go to our:

Basics Electronics 1A

We also have two Metal Detector Projects:

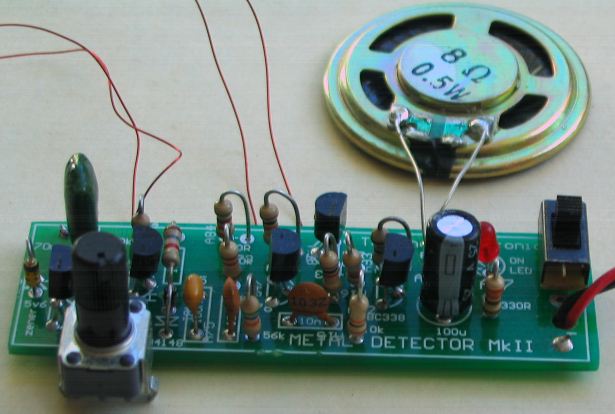

Metal Detector MkI

Metal Detector MkII

BASIC CIRCUITRY of

METAL DETECTION

by

Charles D. Rakes

Note by Colin Mitchell:

The first part of this discussion is a very old article using US imperial measurements,

by Charles D. Rakes. A table of

wire gauges is provided at the end of the article. The rest of the

circuits are from different sources.

All these circuits have about the same sensitivity as the single

transistor circuit shown in fig 7 of Part II (shown below), using

an AM radio as the receiver. They have been included to show the

ingenuity of design-engineers, in an attempt to improve the performance.

Here is a reference from another website with exactly the same views as myself:

The Beat-frequency oscillator (BFO)

is the simplest (and oldest) type of metal detector technology and is a good

starting point for learning how metal detectors work. The basic beat-frequency

metal detector employs two radio frequency oscillators which are tuned near the

same frequency. The first is called the search

oscillator and the other is

called the reference oscillator.

When a metallic object disturbs the magnetic field of the search coil, the frequency of the search oscillator shifts slightly and the detector will produce a signal in the audio frequency range.

Although once popular, BFO's are no longer being made by professional metal detector manufacturers. They are simple and inexpensive, but do not offer the accuracy and control of modern PI or VLF detectors. Attempts have been made to add new features such as discrimination and more advanced models were produced in the 1970s, but they were soon replaced by recent, more sophisticated technology.

BFO designs are still used in cheap hand-held devices and in low quality, toy type detectors.

The Simplest Metal Detector Circuit is also shown below and it

only requires 4 components.

Using a Faraday Shield around the search coil will reduce the effect of

the ground altering the frequency if the ground has a large amount of

iron in the rocks. Simply wind aluminium foil around the turns of the

search coil and leave a small gap where the wires exit.

It is pointless going to a lot of work building a complex receiver (as

shown in a number of the circuits below) as the result will be no better

than the simplest circuit.

All these circuits are limited to picking up a coin at 90mm to 150mm.

Basically, a 90mm coil with pick-up to 90mm and 150mm coil will pick-up

to 150mm.

An AM radio will detect the change in frequency of a few cycles at 150Hz

and you cannot get better than that.

To get a deeper penetration, you need to deliver very high energy to the

coil to produce magnetic flux that enters the ground and gets stored in

the gold nugget.

The coil is then turned off and the circuit listens for the collapsing

energy from the gold nugget being released and detected by the coil.

This is called Pulse Injection technique and will be covered in

later circuits.

For now, here are some simple circuits:

Metal Detection Basics

One of mans greatest challenges

throughout history is to see what cannot be seen, to detect what is

hidden, and to reap riches from these treasures. This visit were going

to look at some very basic metal-detection circuits. Now don't get me

wrong; the circuits we'll share here most likely will never locate a

valuable treasure, but they can be put to use performing other more

practical applications. However, in the early days of the last century,

even the simplest of metal detectors were successful in discovering

some very valuable buried treasures. Simplicity often is the best route

to take in solving a seemingly difficult task. Never give up on an

electronic adventure because you don't have the latest and greatest

equipment.

Ferrous Ferrets

Our

first example of a ferrous detector

is a simple mechanical device shown in Fig. 1.

The detector is a modified balanced scale, which indicates ferrous

objects and magnetized items. A magnet is attached to one end of the

arm and a simple north/south scale is attached at the opposite end. A

pivot is located near the magnet end of the arm and a slide balancing

weight is on the opposite end.

The magnetic scale should be balanced with no ferrous items near by. Any

non-magnetized ferrous object positioned below and close to the magnet

will cause the pointer to go up due to the magnetic attraction.

The magnetic scale should be balanced with no ferrous items near by. Any

non-magnetized ferrous object positioned below and close to the magnet

will cause the pointer to go up due to the magnetic attraction.

A magnetized object with the south pole facing up will cause the pointer

to go down, and when the north pole faces up the pointer will rise. This

ultra-simple magnetic detector is very sensitive and will easily

determine what objects are ferrous and the polarity of magnets.

Electronic Ferrous Ferret

Our first electronic metal detector circuit, see Fig. 2, uses a Hall

Effect sensor to detect weak permanent magnetic fields. Almost all

ferrous objects retain some degree of magnetism, and those that do are

easily detected with our Hall Effect ferrous-detector circuit.

Fig. 2. The electronic version of the Ferrous Ferret uses a

simple Hall Effect IC.

Weak magnetic fields can be detected with this easy-to-build device.

The HAL 115UA-C IC Hall Effect sensor is the heart of the weak-field

detector circuit and is available for less than a buck from Digi-Key.

This Hall Effect sensor is a bipolar device that is sensitive to a

magnet's north pole on its branded side and to the south pole on the

opposite side. The branded side, see Fig. 3, is the side that displays

the part number.

Fig. 3. Let's get up close and personal with our friend—the HAL

I15UA-C.

The branded side-where the part number is displayed—is sensitive to a

magnet's north pole,

while the opposite side is sensitive to a magnet's south pole.

The sensor's output (pin 3) is normally low when no external magnetic

field is present. Placing a magnet with its north pole facing the

branded side of the sensor will cause the output at pin 3 to go high.

Placing a magnet with its south pole facing the non-branded side will

also cause the output to go high.

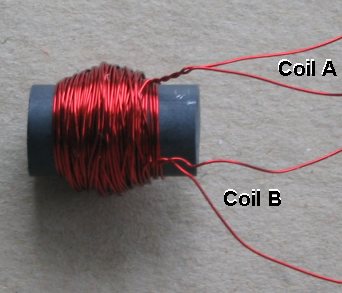

Fig. 4. Utilizing some skill and patience, inductors can be

hand-wound.

Here is a simple diagram showing the typical inductor needed for

metal-detector circuits.

Here's how the circuit operates. Two gates of a 4093 quad, 2-input, NAND

Schmitt trigger IC are connected in a low-frequency square-wave

oscillator circuit operating at about 100 Hz. The output of gate "C"

drives the base of Q1, which is connected in an emitter-follower circuit

supplying the 100-Hz signal to L1. Inductor L1's drive level is set by

R6. The output (pin 3) of IC2 is connected to an LED and a metering

circuit.

Inductor L1 supplies a low-frequency AC bias to the backside of the Hall

Effect sensor, IC2. This AC bias in effect increases the Hall Effect

sensitivity many times over and also allows it to detect both north and

south pole magnets from the branded side; however, the circuit is much

more sensitive to north pole fields. The arrangement of L1 and the Hall

Effect sensor is shown in Fig. 5.

Fig. 5. The Hall Effect IC works in conjunction with the

inductor.

A low-frequency AC bias is supplied to the backside of the IC via the

inductor.

The Hall Effects output waveforms are shown in Fig. 6. The waveforms are

observed at pin 3 of the Hall Effect IC. Output waveform "A" is set by

adjusting R6 for a symmetrical output without any ferrous metals in the

pick-up area. If a scope is not handy, a DC voltmeter can be used to set

the output to about 4.5 volts. This setting will produce an output

waveform very close to the one shown in Fig. 6A. The "B" output waveform

occurs when the north pole of a magnet is brought in proximity of the

Hall Effect sensor. The south pole of a magnet produces the output

waveform shown in Fig. 6C.

Fig. 6. Here are the waveforms that might come from pin 3 of IC2.

Resistor R6 can be adjusted to calibrate the circuit.

Winding L1

Inductor L1 (see Fig. 4) is fabricated by jumble winding 500 turns of

#32 enamel-covered copper wire on a

¼-inch diameter ferrite rod. The rod's actual diameter and length are

not critical, and any size rod material from ¼inch to ½inch in diameter

will do. The rod's length can be anything from 1 inch to 3 inches. The

type of rod material suitable for this application can be salvaged from

an old AM transistor radio or some older TVs.

If the rod material cannot he located, don't give up 'cause there are

other paths to take. A relay coil with a resistance of 10 ohms or

greater will generally work for L1. Some miniature audio transformers

have straight sections of laminations that can be used in place of the

rod material. Most of the rod material I've used and have recommended

here is actually designed for much higher frequency use. As a last ditch

effort, try a number of small nails taped together as a core for L1 and

see what happens. Here's a great place to experiment with various coil

core materials and windings to improve or vary the circuit performance.

Keep me informed on your efforts.

Try This One

Something else came to mind after disassembling the circuit, and due to

time restraints I was never able to check it out. I would like to

challenge you to do so. What if a second Hall Effect IC sensor was added

to the circuit but placed beside IC2 with its branded side facing L1's

core?

Fig. 5. The Hall Effect IC works in conjunction with the inductor. A

low-frequency AC bias is supplied to the backside of the IC via the

inductor.

Duplicate IC2's circuitry with the new IC, but leave out the metering

circuit. See Fig. 7 for details. Try to get like waveforms from both

circuits by adjusting R6 and positioning the two ICs on the end of L1.

Connect one lead of a digital DC voltmeter to pin 3 of IC2 and the other

meter lead to pin 3 of the added IC. If I'm correct, the circuit should

be as sensitive to the south pole of a magnet as the original circuit

was to the north pole. If not, try connecting a DC voltmeter to the

output of IC2 and another voltmeter to the output of the added IC. IC2

should remain more sensitive to the south pole of a magnet, and the

added IC should be more sensitive to the north pole.

All Metals Detector Circuit

Our next metal detector circuit takes us back into the early years of

the last century where tubes were king and semiconductors were only

diodes. It was discovered early on that any metal object placed near the

tank circuit of an oscillator would shift its frequency either up or

down. A tank circuit is the combination of an inductor and capacitor

that make up a tuned circuit. Ferrous metals near the inductor of a

tuned circuit cause the oscillator's frequency to go down and

non-ferrous metals cause the frequency to increase. This is the basic

effect that the Beat Frequency Oscillator (BFO) type of metal detector

uses to detect all metals. Figure 8 shows a block diagram of the

circuits making up a typical BFO detector. A search loop is usually

wound in a circular fashion to serve as the inductor in the search

oscillator's tank circuit. The reference oscillator is very similar to

the search oscillator with a much smaller inductor, which is usually

shielded from the search loop. RF signals are taken from both

oscillators and fed to a common mixer, where the sum and difference

frequencies of the two oscillators are mixed. The sum frequencies are

filtered out, leaving only the audible difference frequencies to pass on

to the amplifier and headphones.

Fig. 7. Increase your odds at detection with this simple modification.

An additional Hall Effect IC is added to balance the circuit's

sensitivity to the north and south magnetic poles.

Fig. 7. Increase your odds at detection with this simple

modification.

An additional Hall Effect IC is added to balance the circuit's

sensitivity to the north and south magnetic poles.

As a practical example, we'll set the search oscillator up to operate at

a frequency of 100,100 Hz, and the reference oscillator to a frequency

of 100,000 Hz. The difference frequency between the two oscillators is

an audible 100 Hz that is fed to the headphones. The search coil is then

moved over a small ferrous metal object causing the oscillator to drop

in frequency to about 100,050 Hz. The audible 100 Hz tone drops to 50 Hz

indicating a metal object is located somewhere near the search loop. A

non-ferrous object near the loop will cause the oscillator to increase

in frequency and produce a higher audio output tone. A carefully

adjusted BFO metal detector can be used to discriminate between ferrous

and non-ferrous metals.

Fig. 8. The popular loop-detector circuit has been a mainstay for

many treasure hunters.

A set of headphones allows the user to hear an indication of ferrous

material and magnetic fields.

Two-Transistor BFO Detector

One of the simplest BFO metal locators to build is the two-transistor

circuit shown in Fig. 9.

Fig. 9. This is the schematic for a Beat Frequency Oscillator

metal-detector.

Two transistors are used as the oscillators in this circuit.

The circuit may be set up to operate on any frequency between 50,000 Hz

to over 1 MHz by selecting the tank circuit components. Just about any

good general-purpose NPN transistor suitable for low RF applications

will work just fine. The search loop can be as small as a dime or three

feet or larger in diameter. A small loop works best for small objects

buried shallow and a large loop works best for large objects buried at

greater depths. The two oscillator circuits should be separated and

shielded from each other to reduce frequency pulling between the two. A

really well constructed BFO detector will be able to operate with a

difference of less than 100 Hz between the two oscillators. The lower

the audio output tone the easier it is for the ear to tell a small

frequency shift. The detector's maximum sensitivity is obtained when the

two oscillators are operating just a few cycles apart. Believe me, this

is not an easy task to accomplish, but one well worth the effort.

Here's how the simple BFO detector operates. Transistor Q1 along with

its associated components make up a Colpitts oscillator circuit with the

search loop, C1 and C3 forming its tuned circuit. Transistor Q2 with its

associated components make up another Colpitts oscillator circuit with

L2, C2, and C4. forming the tuned circuit. The emitters of Ql and Q2 are

coupled together through R1, R2, and the low-impedance headphones. This

circuit arrangement functions as a simple RF mixer circuit. The audio

frequencies are fed to the headphones, and the RF frequencies are

bypassed to ground through C8.

Winding And Scrounging

The loop may be wound on almost any round insulated non-metallic form,

such as wood or plastic. Inductor L2 can be an old ferrite rod antenna

coil removed from an AM transistor radio, or one can be made by winding

a coil on a round insulated form. Let me offer the following winding

suggestion to get you going on building the BFO circuit. Locate a 10- to

12-inch wood or plastic hoop that's about 3/4-inches wide and close wind

ten turns of #18 to #22 enamel-covered copper wire evenly around the

forms. Tape over the wire with plastic electrical tape and connect to

the circuit with a length of two-wire zip cord. If an antenna coil

cannot be found for L2, then close wind about 80 turns of #22

enamel-covered copper wire on a 1-inch plastic pill bottle or plastic

pipe.

One important thing to do in selecting the two inductors is to be sure

that the reference oscillator can tune to the same frequency as the

search oscillator. If a frequency counter is available then the chore

will be super easy. If not, some experimenting with different pairs of

capacitors (C1 and C3 or C2 and C4) will be necessary to bring both

oscillators to the same frequency.

Part II

Single Transistor Circuit

Before getting into the circuitry, we had better take a quick look at

how the single-transistor detector system operates. I'm sure that at

some time you've heard a whistle or tone while tuning your AM broadcast

receiver or, even more likely, when listening to an AM short-wave

broadcast station. In radio circles, this is referred to as a heterodyne

signal. An AM receiver detecting two RF signals, which are very close in

frequency, usually causes this condition. If the two RF frequencies are

less than a few kHz apart, an audio tone (difference frequency) will be

heard. This is basically how our single-transistor detector circuit

operates.

In our single-transistor circuit, see Fig. 1, only one RF oscillator

circuit is used. The other RF signal is supplied by one of many AM

broadcast radio stations. A portable transistor AM radio receives the

two RF signals and outputs an audible tone. The mixing and audio

amplification is handled by the transistor radio. If either RF signal

shifts in frequency, the audio tone will increase or decrease by the

same amount. Since the frequency stability of all licensed AM broadcast

stations is rock solid, only our search oscillator will produce a shift

in frequency. The end result is a detector that operates like our

two-transistor circuit, but requires less parts and time to construct.

The oscillator circuit in Fig. 1 is very similar to the oscillators used

in our previous circuit. Transistor Q1 is connected in a Colpitts

oscillator circuit with components C2, C3, C5, C6, and LI making up the

oscillator's tuned circuit. Changing any one or any combination of these

components will vary the oscillator's operating frequency.

Increasing the value of any capacitor will lower the oscillator's

frequency and decreasing the value will increase the frequency.

Increasing L1's inductance will also cause a decrease in frequency and

vice versa.

Fig. 1. Here is the schematic for the single-transistor circuit.

Transistor Q1 is a general-purpose, NPN transistor; and it serves as the

heart of a Colpitts oscillator circuit.

PARTS LIST FOR THE SINGLE-TRANSISTOR CIRCUIT (FIG. 1)

SEMICONDUCTORS

Q1—2N3904, or similar general-purpose NPN transistor

RESISTORS

(All resistors are ¼-watt, 5% units.)

R1—1000-ohm

R2—270,000-ohm

CAPACITORS

C1—.01-uF, ceramic disc

C2—.0001-uF, ceramic disc

C3—-.005-nF, ceramic disc

C4—.1-uF, ceramic disc

C5 4 to 34 pF, 7-mm, ultra-miniature trimmer, Mouser part

#24AA113

C6— 12-100 pF, Mouser part #242-3410-70

ADDITIONAL PARTS AND MATERIALS

S1—SPST switch

L1—Loop, see text

The 6 turns of copper wire can be wound on a rigid material, such as

wood or plastic.

Fig. 3. This detailed diagram of the loop shows the leads

extending from the copper wire, as well as the makeshift Faraday shield.

Fig. 4. Here is an artist's diagram of the completed

metal-detector unit.

Any inexpensive AM transistor radio can be used in conjunction with the

detector.

Building The Loop

The search loop may be constructed in several different ways; however,

the method offered here should get you headed in the right direction.

Refer to Fig. 2 as a guide for constructing the loop. The loop form

should be constructed from non-metallic and non-moisture-absorbent

material. A sealed wood form will do, and it can be either solid or

hoop-like. The form should be % to 1 inch wide to allow room for the

coil windings. Close wind six turns of #20 enameled or insulated wire on

the form. Wrap the windings with at least two layers of good quality

plastic electrical tape. Put the loop aside and construct the oscillator

circuit on a piece of multipurpose PC board with pre-drilled holes.

Stability is one of the most important considerations in building any

stable oscillator circuit, so keep all component leads short and solidly

mounted.

The two variable capacitors should be mounted in a manner that allows

tuning from outside the enclosure. In order to achieve the best results,

the circuit should be housed in a metal cabinet to which the circuit

ground is connected. Temporarily connect the loop to the circuitry with

about 30 inches of shielded microphone cable or 2-conductor intercom

wire. Any wire gauge from #18 to #24 will do. Actually two insulated

wires may be twisted together by hand and used.

Place the loop away from any metal object and apply power to the

circuit. Locate a transistor radio near by and tune in a station

somewhere near the middle of the dial. Adjust both C5 and C6 to a

frequency that will heterodyne with the broadcast station. If nothing

happens, it is most likely that the oscillator is not operating near the

desired frequency. Now, how do we determine if the oscillator's

frequency is too low or too high? Naturally, a frequency counter would

be the easiest way to determine the oscillator's frequency. If one is

not available, what then? A shortwave receiver that runes both below and

above the standard AM broadcast band can be used to ferret out the

oscillator's frequency.

Once the oscillator's frequency is determined, adjustments can be made

to move the frequency into the broadcast band. Reducing the total

capacitance of the oscillator's tuned circuit or lowering the inductance

of the loop will raise the frequency. Lowering the frequency is

accomplished by increasing the capacitance of the tuned circuit or by

increasing the inductance of the loop. Removing or adding a turn to the

loop is a good method to use if the oscillator is way off frequency.

Adding A Faraday Shield

The search loop normally scans the ground in a parallel manner in search

of metal objects. The loop's parallel position to the ground forms a

capacitance to ground, which shifts the oscillator's frequency. As the

loop moves up and down above the ground, the oscillator's frequency

shifts in a like manner. Adding a Faraday shield to the loop will help

in reducing the ground-effect frequency-shift problem.

The Faraday shield is a metal shroud that is formed around the loop with

an insulating gap in the middle. A shield can be formed out of aluminum

foil by cutting a length that's 3 inches wide and long enough to go

almost completely around the edge of the loop while leaving a gap of 1

to 2 inches in the middle, see Fig. 3. Once the aluminum foil is formed,

add a 4-inch length bare wire under the foil at one end and glue the

shield in place. Place the loop on a flat surface and place a solid

object on top to secure the foil to the loop form. After the glue dries,

connect the other end of the bare wire to the loop's ground-end

connection.

An old broom handle or dowel rod is attached to the middle of the loop

and serves as the handle and support for the loop and detector circuit.

See Fig. 4. The AM radio may be attached to the handle as well or

carried separately.

Position the loop over the area to be searched and tune the oscillator

to produce an audible beat frequency tone. Maximum sensitivity is

achieved when the oscillator is within a few cycles of the broadcast

station. This detector will detect all types of metal, so be ready to

dig, and then dig some more.

Fig. 5. The crystal-filter metal-detector circuit is shown above.

The narrow band-pass of the crystal allows for a high sensitivity to

minute frequency changes.

PARTS LIST FOR THE CRYSTAL-FILTER DETECTOR (FIG. 5)

SEMICONDUCTORS

D1, D2—1N9L4 silicon signal diode

Ql, Q2—2N3904, or similar general-purpose NPN transistor

RESISTORS

(All resistors are ¼ watt, 5% units.)

R1,R3— 1000-ohm

R2—270,000-ohm

R4—-See text.

CAPACITORS

C1—.01uF ceramic disc

C2—,0001uF ceramic disc

C3—.005uF ceramic disc

C4— 0.1uF ceramic disc

C5—See Parts List for Fig. 1

C6—See Parts List for Fig. 1

ADDITIONAL PARTS AND MATERIALS

XTL1—1-MHz crystal

Ml—50-uA to 1-mA meter

Metal cabinet, PC board material, etc.

Crystal-Filter Detector

Our next entry is a version of one of my favorite metal-detector

circuits. A loop and an oscillator circuit similar to the one in our

previous detector are the basic ingredients used in the crystal-filter

detector. The addition of an emitter follower gives isolation to the

oscillator and supplies a low-impedance source for the crystal. The

output is rectified by D1 and D2 and fed to the meter. Take a look at

Fig. 5, as you continue to read the circuit description.

Here's a brief description of how the crystal-filter metal-detector

circuit operates. The oscillator is tuned to the series resonance

frequency of the crystal, which can be any frequency from 100kHz to over

1MHz. However, in our circuit, a 1-MHz crystal is used. When the

oscillator is operating at the crystal's frequency, the output at the

meter is at maximum.

Any shift in the oscillator's frequency will cause a reduction in the

meter reading. The circuit is very sensitive to small frequency shifts

due to the crystal's narrow band-pass characteristics in the series

mode. The basic loop construction used in the previous detector circuit

may be used here as well.

This detector's circuitry should be constructed in the same manner as

our previous circuit. If any component moves or vibrates during use, the

meter will falsely indicate a detected object. Build it solid. The

choice of the meter used for M1 can vary from a sensitive 50-uA to a 1mA

movement. The value of R4 is selected for a full-scale meter reading

when the oscillator is operating at the series-resonance frequency of

the crystal.

Fig. 6. The detector shown in the above diagram is excellent for

deep level searches.

The "90-degree out-of-phase" relationship of the two square loops helps

limit cross-interference between the transmitter and receiver, thus

eliminating feedback during operation.

Transmitter/Receiver Detector

Our last detector circuit is suitable for locating large metal objects

at greater depths—feet instead of inches. This two-box detector has been

around for about 75 years and is still one of the most popular

deep-searching detectors. The basic system is shown in Fig. 6.

Two non-metallic boxes serve as the 2 housing for the electronics and

the forms for the loops. The transmitter and receiver boxes are mounted

on a 3-foot-long wood handle, with the receiver placed in a horizontal

position and the transmitter in a vertical position. This 90-degree

relationship between the transmitter and receiver allows for minimum

transfer of signal between the two loops. Placing a large metal object

between the two loops causes the transmitter's field to distort,

allowing some of the signal to reach the receiver's loop. The signal is

amplified by the receiver and indicated on the meter as metal detected.

Building The Transmitter

We'll start with the transmitter circuit first, (see Fig. 7) because it

is the simpler of the two units. The transmitter circuit is very similar

to our previous two oscillator circuits, with a slight variation in the

base bypass circuit. The values of frequency-determined capacitors, C1

and C2, are the same. Depending on the size of the loop, they can vary

from .01 to .1-LlF.

The receiver loop normally requires a capacitor equal to Vi the value of

C1 or C2 in the transmitter circuit. The transmitter loop is tuned with

C1 and C2, which are always the same value. The actual value of

capacitance across the transmitter loop is Vi the value of either C1 or

C2. It is most important that both loops are tuned to the same

frequency.

About any loop size from 8 to 12 square inches will do, but we'll stick

to the 12-inch box and offer values for that size. The loops are formed

by close winding 20 turns of #24 to #26 wire around each housing. Run

about 8 inches of wire from each end of the loop to the inside of the

housing for circuit connections. Tape the winding in place with plastic

electrical tape.

The operating frequency will be somewhere between 35 kHz and 50 kHz. The

capacitor values for C1 and C2 are 0.1uF for the transmitter and .05-uF

for C1 in the receiver circuit. Less turns or smaller loops may be used

for higher frequency operation. Try and keep the operating frequency

below 200 kHz, as this type of metal locator works best at low

frequencies.

Fig. 7. The transmitter circuit in the above schematic operates

in a range of 35 to 50 kHz.

The oscillator circuit is similar to the previous two mentioned.

PARTS LIST FOR THE TRANSMITTER (FIG. 7)

SEMICONDUCTORS

Q1—2N3904. or similar general-purpose NPN transistor

CAPACITORS

C1.C2— .01 to 0.1uF, ceramic disc (see text)

C3, C4— 0.1-u.F, ceramic disc

RESISTORS

(All resistors are ¼watt, 5%)

R1—1000-ohm

R2—270,000-ohm

R3—220.000-ohm

ADDITIONAL PARTS AND MATERIALS

S1—SPST switch

L1—Loop, see text

Building The Receiver

The receiver (see Fig. 8) is a simple two-transistor RF amplifier

circuit with an isolated emitter follower input. The RF signal is picked

up by the loop and coupled through Q1 to the input of the first RF

amplifier stage, Q2. Transistor Q2's RF gain is set by R10. The signal

from Q2's collector is fed to the base of Q3, and Q3's output is coupled

to a two-diode detector circuit. The DC output is indicated by Ml.

The receiver circuitry will fit on a 2 x 3-inch piece of multipurpose PC

board material. Mount the components close to the board with short leads

and keep the input components away from the output circuitry. The meter

can be any DC type with sensitivity of 50-uA to 1-mA. If a 50uA meter is

used, R11 may need to be increased to a 10K potentiometer. Mount the

circuit in the receiver box and connect the loop.

Mount the transmitter box on one end of the wood handle and the receiver

on the other. The receiver will need to be mounted so that it can be

tilted up and down to obtain a balance between the two loops. This can

be accomplished by using a small hinge attached to the end of the handle

and the receiver housing. Once the balance point is found, the receiver

can be mounted in that position.

Fig. 8. The receiver circuit.

PARTS LIST FOR THE RECEIVER (FIG. 8)

SEMICONDUCTORS

Q1-Q3—2N3904, or similar general-purpose NPN transistor

D1, D2—1N914 silicon signal diode

CAPACITORS

C1—.005 to .05-uF ceramic disc (see text)

C2 0.1—.05-uF ceramic disc

C5-C9 — 0.1 uF ceramic disc

C10— 470uF 25WVDC electrolytic

RESISTORS

(All resistors are ¼watt, 5%)

R1,R2— 100,000-ohm

R3-R5—1500-ohm

R6— 100-ohm

R7—470-ohm

R8, R9—220,000-ohm

R10— 1000-ohm potentiometer

R11—2500-ohm potentiometer

ADDITIONAL PARTS AND MATERIALS

S1—SPST switch

M1—50-uA to 1-mA DC meter

L1—Loop, see text

Simplest Metal Detector Circuit

The simplest metal detector circuit consists of 4

components.

The detection-coil consists of 70 turns of 0.3mm wire 120mm diameter.

Place an AM radio near the search-coil and tune it to pick up a squeal.

When a coin is placed near the coil, the tone will alter.

The circuit operates at about 250kHz and the the radio picks up a

harmonic. It will detect a bottle-top at about 90mm.

Another simple Metal Detector Circuit consists of two coils that overlap

to provide feedback:

Place an AM radio near the coils and a tone will be heard.

Simple BFO Metal Detector

The first two transistors are deigned to produce the exact same

frequency. The result is fed to the third transistor to produce a

beep-beep-beep in the piezo speaker.

When a metal object is detected by L1, (the search coil) the beeping

increases.

The performance of this circuit is no better than the single transistor

circuit above and an AM radio. When it is all boiled-down, the first

transistor drives the coil and the frequency of the circuit changes when

the inductance of the coil is altered by a metal object near it.

The second and third transistors are equivalent to an AM radio by

detecting the frequency of the oscillator and producing a result that is

the difference between the frequency produced by the first transistor

and the frequency produced by the second transistor.

The next circuit is even more complex.

It uses integrated circuits (IC's) to detect the difference between the

two frequencies.

The circuit is very old. All the IC's can now be replaced by an 8-pin

microcontroller and the circuit will be much simpler.

Don't forget, it is no better than a single transistor and an AM radio

and is not worth constructing, however the text is interesting . . .

Simple, sensitive metal detector

Phil Wait

The metal detecting hobby is enjoying quite a boom at the moment and

treasure hunters are not just after gold. The price of the precious

metal has risen in recent months, at around $1,600 an ounce it's worth

going after. Old coins and relics fetch high prices too, so there's lots

to find out there...

METAL DETECTORS depend on detecting one of several effects that can be

observed when a metal object influences the magnetic field surrounding a

coil of wire carrying an alternating current. The principal effects are:

the pattern of the magnetic field surrounding the coil will be altered

and the inductance of the coil will change.

The various types of metal detector devised exploit these changes,

electronically detecting the alteration induced in the coil by the

metallic object. Non-metallic objects or material can also affect the

coil in similar ways.

There are three basic methods employed to exploit the above effects.

"Induction Balance" (IB) metal detectors employ two coils. One is driven

by a modulated oscillator. The other is connected to a detector and

amplifier. The two coils are carefully positioned with respect to one

another such that the receiver coil picks up very little of the energy

radiated by the transmitter coil when no metal or mineral material is

nearby. When the coils are brought near a metal object, the field

pattern is distorted, greatly increasing the transmitted energy picked

up by the receiver coil. The modulated signal is detected and can be

indicated by amplifying the recovered modulation to speaker level as

well as indicating it on a meter. For obvious reasons, this type of

metal detector is often referred to as a "transmit-receive" or TR

detector, sometimes as an IB/TR detector. Chief advantages are good

pinpointing ability and good depth penetration, and they are not

sensitive to small ferrous objects.

Sensitivity suffers badly in mineralised or ironstone ground.

Most IB detectors operate at a frequency between 85 kHz and 150 kHz. As

they are badly affected by mineralised ground a technique was developed

using very low frequency to energise the transmit coil. The 'VLF' types

operate at frequencies around 4-6 kHz, a frequency range which

penetrates all types of soil quite well. However, they need to run at a

fairly high power to achieve sufficient sensitivity with small objects,

hence battery drain is quite high, and pinpointing ability is poor.

"Pulse Induction" detectors employ coils in the search head that are set

up in much the same manner as the IB detector. However, the transmitter

is pulsed so that high energy bursts are transmitted by the search coil.

The receiver then

compares the phase of portion of the received pulse with the transmit

signal. When a ferrous or magnetic object is brought near the search

coils the phase of the received signal is advanced with respect to the

transmit signal. The opposite occurs when a non-magnetic conductor is

brought near the search coils. Thus, this type of detector can

effectively 'discriminate' between ferrous and non-ferrous metals as

well as exclude ground effects — simply by setting the detection

circuitry to exclude signals of the unwanted phase characteristics.

Thus, a "Ground Exclusion" control is often featured with these

detectors. As the strength of the received signal also varies, depending

on the 'target' object's characteristics, this effect may also be

included in the detection process.

Clearly, an IP detector presents many problems to the home constructor.

The simplest technique detects the change in inductance of a single

search coil. If this coil is part of the tuned circuit of an oscillator,

then comparing the frequency of the 'search' oscillator with a stable

reference oscillator will indicate the presence of a metal object. This

detector is called the "Beat Frequency Oscillator" or BFO type. The two

oscillators are set such that there is a slight difference in their

frequencies and their outputs mixed. The resultant will be a 'beat'

frequency which is equal to the difference between the two oscillator

frequencies. The main advantages of this type are simple circuitry and

setting up along with good pinpointing ability. In the past, most

published designs have suffered from a distinct lack of sensitivity as

well as poor tuning stability. A cunning mixing technique and a few

other fillips can overcome these problems.

Hence, our new metal detector is a BFO type incorporating some modern

refinements. It has proved to have similar sensitivity to our IB

detector, the ETI-549, but is generally easier to build and set up,

there being no critical adjustments.

Design features

Our new metal detector has three controls: COARSE frequency adjust, FINE

frequency adjust and VOLUME on/off The coarse frequency control is used

to initially set the frequency of the search oscillator, compensating

for the various factors affecting any drift in this oscillator (mainly

temperature and battery voltage). The fine frequency control is then

used to set the note to a low pitch when the detector is placed over the

ground, permitting compensation for the effect of the ground on the

frequency of the search oscillator. The volume control adjusts the

loudness of the output from the speaker.

The two main design problems this type of detector presents are the

frequency stability of the two oscillators and the minute frequency

change which has to be detected.

The search oscillator we finally used was settled on after some

experimentation. Our first try employed an LC oscillator built around a

CMOS gate chip. This proved to be not as stable as we required and we

found that trying to obtain dc control of the frequency by varying the

supply rail voltage had drawbacks. After some experimentation with

oscillator configurations we hit on a discrete component oscillator

which we found behaved much as we were seeking.

The search coil in the circuit we used is the inductor in a Colpitts

oscillator. However, this particular circuit may be a little unfamiliar

to many readers. To increase the RF current in the coil, it is placed in

the collector circuit of Q1. Feedback is between collector and emitter

and the base is effectively at RF ground. The frequency determining

capacitance of the tuned circuit is 'tapped' to provide feedback, C2 and

C3 performing this function. Careful attention has been paid to the

basic frequency stability of this oscillator. Good quality styroseal

capacitors have been used for C2 and C3. These have a temperature

coefficient roughly opposite to that of other temperature influences on

the frequency of the oscillator. In general, the short-term stability of

this oscillator is quite good.

The particular circuit configuration of the oscillator gave us a very

useful bonus — dc control of the oscillator frequency over a small range. Varying the base bias on a transistor will

vary the collector-base capacitance. In this circuit, the c-b

capacitance is part of the overall 'stray' capacitance that determines

the exact frequency of oscillation. As the base bias is increased the

c-b capacitance decreases, increasing the oscillator frequency. In this

way, the oscillator frequency can be varied over a range of about ten

percent. We have provided two controls, the FINE control providing a

variation of about one-tenth that of the COARSE control.

The search oscillator is loosely coupled via a 47p capacitor to a

following CMOS Schmitt trigger and two inverters which square the

output. The loose coupling isolates the oscillator from the subsequent

circuitry, further enhancing die stability of the search oscillator.

For the reference oscillator, we chose to use a crystal, because of its

inherent stability. It has been argued that if an ordinary LC circuit is

used for the reference oscillator it will have similar drift

characteristics as the search oscillator and the overall drift will be

reduced. In fact, the reference oscillator can be made using a standard

455 kHz IF transformer. In practice however the two tend to drift at

markedly different rates. We think the best approach is to make both

oscillators as stable as possible. Hence the crystal — which is an

easily available type and cheaper than an IF transformer!

The reference oscillator is a simple 'inverter' crystal oscillator built

around one gate from a CMOS quad NAND gate, IC2. This has a square wave

output and drives a divide-by-four circuit, IC3, via the other three

gates in IC2, acting as buffers.

The crystal we used is a 3.579545 MHz type (NTSC chrominance sub-carrier

frequency) commonly available from a number of suppliers. The output

of IC3 is at a frequency of about 890 kHz. The exact frequency is

unimportant, just so long as its stable.

The search oscillator operates at a little above 100 kHz, about

one-eighth of this frequency.

The secret of our metal detector's overall sensitivity lies in the mixer

circuit. This employs one section of a 4013 flip-flop. The reference

oscillator's divider output (at 890 kHz) is applied to the D input of

IC4a and the squared-up search oscillator's output is applied to the

clock input. If the clock frequency (i.e the search oscillator

frequency) changes by 1 Hz, the output beat (from the Q output of IC4a)

will change by 8 Hz (see 'How it Works'), thus considerably multiplying

the smallest changes in oscillator frequency.

The output of the mixer is fed to a simple audio amplifier driving a

loud-speaker. The search and reference oscillators must be well

decoupled from each other and buffered from the mixer stage to prevent

'pulling' of the oscillators, which would result in erratic operation,

especially when set for a low frequency output. We have used supply line

decoupling as well as buffer stages after each oscillator. We also found

it necessary to use a separate battery for the audio stage to prevent

the very short, but high current pulses to the audio stage affecting the

oscillators.

The search coil

The most important characteristic of the search coil is its size.

Surprisingly enough the actual inductance doesn't seem to have much

effect on sensitivity. The greater the coil diameter the greater the

penetration depth, but the less sensitive it is to small objects. As a

general rule the penetration is about equal to the search coil diameter,

while the sensitivity is roughly proportional to the cube of the object

diameter (as expressed as a function of the search coil diameter).

Sensitivity is also inversely proportional to the sixth power of the

distance between the coil and the object.

All this means is that if the object size is halved the sensitivity is

reduced to one-eighth. Also, if the depth is doubled the sensitivity is

reduced to one sixty-fourth. Its easy to see why all metal detectors

which are designed to pick up small objects use small coils, (150 to 300

mm diameter) and really only skim the soil surface. If the search coil

is doubled in diameter for greater penetration the sensitivity to small

objects falls to one-eighth. You rapidly encounter the law of

diminishing returns.

Some of the more expensive metal detectors improve the penetration,

while retaining sensitivity, by using a very complex arrangement of

coils which modifies the field pattern. This can be done to some extent

by making the coil on the BFO detector oval in shape.

We chose a round coil of 150 mm diameter to give good sensitivity to

small objects giving about 100-150 mm penetration which is easy to

build, but this is open to considerable experimentation. Remember

though, that if the coil diameter is increased the number of turns will

have to be reduced so that the search oscillator remains at the same

frequency (about 110 kHz).

Faraday shield

If the search coil is moved around, the capacitance between it and the

ground or other objects changes. This changing capacitance 'pulls' the

oscillator frequency and can completely swamp out the small change in

inductance we are looking for. The coil can be screened from this

capacitance effect by using a Faraday Shield around the coil. This

consists of a ring of tubing, or in our case — a wrapping of aluminium

foil, around the coil but broken at one point so it does not make a

shorted turn. This shield is then connected to the common supply rail

(0V) on the oscillator.

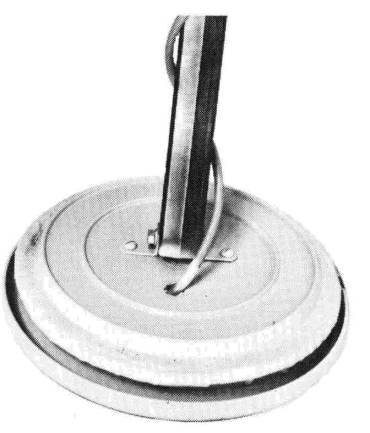

Construction

We have deliberately chosen commonly available mechanical and electronic

components so that construction of this project is as easy as possible —

especially for the newcomer. The search coil is mounted on a 165 mm

diameter plastic pot stand which may be purchased at hardware stores and

nurseries. The electronics are

mounted inside a simple aluminium box attached to a stem made from a

length of tube which extends down to the search coil and serves as the

handle. Connection to shield the search coil is via a length of shielded

cable. The controls mount on one side of the box housing the

electronics. Which side you mount them depends on whether you are right

or left handed. The speaker mounts on the end of the box facing the

operator. As can be seen from the picture, the handle was made with an

upwards bend at the end which you grip. This balances the instrument

reasonably well, avoiding arm strain.

Construction should commence with the electronics. Mount the components

on the pc board, taking care with the orientation of the transistor (Q1)

and the ICs. Do not substitute another type of capacitor for the

styroseal types specified for C2 and C3 or performance may suffer. The

crystal specified comes with flying leads and may be soldered in place.

Don't use too much heat though, solder quickly and you will avoid

possible damage to the crystal.

The next step is to make the stem. The easiest way is to take a length

of 25mm diameter electrical conduit about 850 mm long and make a bend about

100 mm from one end for the grip. To do this, heat the point of the bend

over a flame (not in the flame) until it softens and then carefully bend

it about 60° from straight.

A length of aluminium tube may also be used for the handle. The bend for

the grip can be made by first flattening the point of the bend somewhat

with a hammer then placing the short piece in a vice and carefully

making the bend. A section of wood dowel or plastic tube should be

placed between the search coil and the end of the metal tube to keep the

mass of metal about 200 - 250 mm away from the search coil. A piece of

wood dowel of the right size, jammed in the end of the aluminium tube,

is generally the easiest way to go about it.

We used a small aluminium box which comes in two pieces. We drilled a

hole in either end of the bottom of this box so that it could be slipped

over the stem (see accompanying photograph). A nut and bolt was used to

secure it to the stem on the side 'below' the grip. The small speaker is

mounted in this part of the box, before it is secured to the stem, on

the end which faces upward toward the operator. A small hole is drilled

in the opposite end and a grommet inserted. This permits entry of the

cable

to the search coil.

The pc board and controls are mounted to the 'lid' of the box. Position

the controls on the side that suits your handedness. Our model was made

for right handed operators.

Now for the search coil. This is wound so that it can be tucked inside

the rim of the up-turned plastic pot stand. First make a cardboard

former of the appropriate diameter. Roll a strip of heavy cardboard

around the rim such that it fits loosely and tape or staple it securely

(to avoid it popping open at an awkward moment).

Lift the former off the pot stand and then wind the coil onto this

former as per the details given in the parts list. Leave a short length

of wire spare on each end to make the connection. Tie the coil up with a

few lengths of string at various places and then slide it off the

former. Now wind two layers of insulation tape around the coil, leading

the two ends out at the same place.

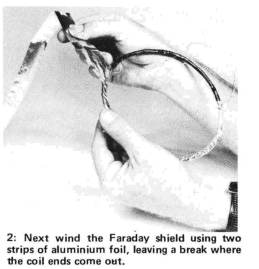

Next, wind the Faraday screen. Cut some aluminium kitchen foil into

strips about 15 mm wide and wind this around the coil to make two layers

but leaving a small gap about 5 mm to 10 mm wide where the coil ends

come out. It is very important that the two ends of the Faraday shield

do not connect as this would make a 'shorted turn' and the coil would

not work as intended.

To secure the foil tightly around the coil and to make connection to

the shield, wind a length of tinned copper wire around the shield with

about a 10mm pitch (i.e: about 10mm between successive turns). The end

of this wire is taken out at the same place as the coil connections.

Now wind another two layers of insulation tape around the whole

assembly. Drill a 3 mm hole in the side of the pot stand and then press

the coil down into the rim with the connecting wires adjacent to the

hole. Pass the wires through the hole. Pour quick- setting epoxy over

the coil to hold it in place.

The search head is mounted to the stem using two right-angle brackets

and a bolt passed right through the end of the stem. Small pieces of

metal here don't seem to adversely affect the operation of the detector.

Solder the coil connections to the twin shielded cable, the Faraday

shield connecting to the cables shield, and glue the cable and wires

underneath the pot stand to hold them rigid. If you wish, the

'underside' of the pot stand may be completely filled with epoxy.

Wind the cable around the stem to keep it mechanically rigid and pass it

through a grommeted hole in the box. Terminate the cable to the pc

board.

Using it

When the construction is complete, turn on the detector, advance the

volume control and rotate the coarse frequency knob. You will hear a

number of 'heterodynes' or beats, one being very strong. This heterodyne

is the one commonly used, the others being odd multiples of the

reference signal beating with multiples of the search oscillator. You

may find that some of these weaker signals are more sensitive to buried

objects than the stronger one.

Set the fine frequency control to midrange and set the course frequency

control to near the strong heterodyne with the search head held away

from the ground. Lower the detector to the ground and you will notice a

frequency shift. This is the effect of the ground and will vary between

different types of soil. Use the fine frequency control to set the beat

to a low pitch and sweep across the surface. A metal object will cause a

change in the pitch which is clearly audible.

The ear is more sensitive to changes in pitch at low frequencies than at

high frequencies and thus it is best to adjust the fine frequency

control to a low pitch that can be heard at a comfortable volume from

the loudspeaker.

Theoretically, the frequency of the search oscillator should increase

when a non-ferrous object comes within range of the search coil and

decrease when a ferrous (or diamagnetic) object is within range. This

effect is difficult to detect in practice as eddy currents in ferrous

materials swamp the effect and they react much the same as non-ferrous

metals. However, minerals such as hematite may show the effect. With the

search oscillator set on one side of zero beat, metal objects near the

search coil will cause the pitch to increase, while magnetic minerals

will cause the pitch to decrease. With the search oscillator set to the

other side of zero beat, the opposite will occur.

You could try a few experiments to show up this effect.

Enough theorising. In general operation, try to keep the search head a

constant distance from the ground and sweep from side to side in a

regular pattern. The right technique is easily developed with a little

practice.

There are a number of books on metal detecting available and these show

the sort of techniques the successful treasure hunter employs.

| HOW IT WORKS The beat frequency metal detector employs two oscillators: a very stable reference oscillator and a search oscillator. The search oscillator uses a tuned circuit designed to be influenced by metal or mineral objects which are brought into its field. The two oscillators are adjusted so they are harmonically related and fed to a mixer. When the search frequency is adjusted so the reference frequency fed to the mixer is eight times the search frequency, the output of the mixer is zero. The search frequency is slightly adjusted so that an output appears from the mixer which is the difference between the two input frequencies. This can be adjusted to an audio tone. When a piece of metal or mineral is brought near the search coil the frequency of the oscillator varies, which in turn varies the output frequency from the mixer. The change in pitch can easily be heard from the speaker. The reference oscillator employs a crystal in a CMOS oscillator circuit using one gate from IC2a. The resistor R6 biases the gate into its linear region. IC2 b, c and d, are used as buffer stages to prevent oscillator pulling and to further square its output waveform. Two flip-flops, IC3a and b, divide the reference signal by four to 890 kHz. The search oscillator uses a discrete transistor in grounded base configuration, with the search coil in the collector. Using the coil in the collector increases the strength of the field around the coil and hopefully overcomes some of the losses in the ground. Feedback is set by the ratio of C2 to C3 from collector to emitter and their value determines the frequency of the oscillator. The base is grounded at RF by C4. By varying the bias on the transistor the inter-element capacitances can be varied. This varies the oscillator frequency as the transistor capacitances form part of the strays in the LC circuit. RV1 and RV2 provide fine and coarse frequency control. The resistors R8 and R9 limit the maximum and minimum voltage on the base to prevent over-dissipation in the transistor or drop-out of the oscillator. The output of the search oscillator is fed to a Schmitt trigger, consisting of IC1a and b, where it is squared and further buffered by IC1c and d. The search frequency is then fed to the mixer. Both oscillators are decoupled from each other by supply line decoupling R1, C1 and R5, C6. The mixer consists of half a dual-D flip-flop. The search and reference frequencies are fed to the clock and D inputs respectively. The flip-flop looks at the reference oscillator (D on every positive transition of the search oscillator clock), and transfers this level to the Q output until the next clock transition. If the two oscillators are exactly evenly harmonically related (i.e: 2nd. 4th, 6th, or in our case 8th, harmonic) the D input will always be the same level at each clock pulse. The output from the mixer at the Q pin will always be the same — no pulses. However, if the search frequency is varied and the D and clock inputs are no longer harmonically related but are changing in phase with respect to each other, after a few clock pulses the D input will no longer be the same — the output will change state. The effect of all this is to produce a chain of square waves at the Q output, the frequency of which is eight times the change in frequency of the search oscillator. Capacitors C8 and RV2 form a differentiating network which feeds a pulse to the audio amplifier, Q2, for each output transition from the mixer. Each cycle from the mixer produces two pulses in the speaker. If the frequency of the search oscillator is shifted one hertz the output of the mixer changes by eight hertz, producing an output of eight pulses per second in the speaker. |

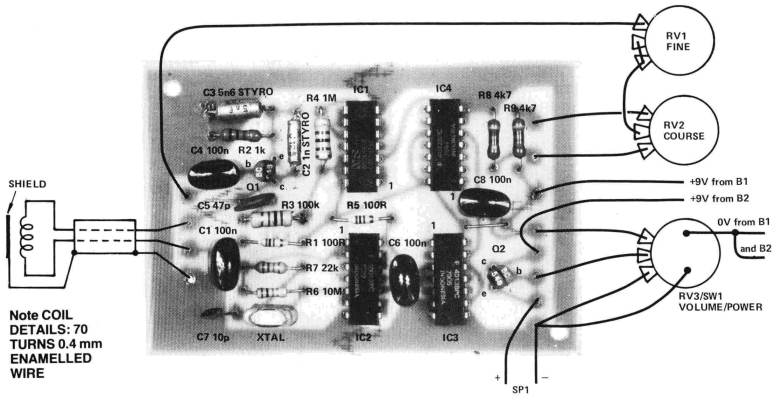

| PARTS LIST Resistors all 1/2W, 5% R1 100R R2 1k R3 100k R4 1M R5 100R R6 10M R7 22k R8 R9 4k7 Potentiometers RV1 10k lin RV2 100k lin RV3 100k log switch pot Capacitors C1 100ngreencap C2 1n styroseal C3 5n6 styroseal C4 100n greencap C5 47p ceramic 06 100n greencap C7 10p ceramic C8 100n greencap Semiconductors Q1, Q2 BC548, BC108, etc. IC1, IC2 . . . . 4001B IC3, IC4 . . . .4013 Miscellaneous SP1 8 ohm speaker B1,B2 9 Volt battery (type 216) Xtal NTSC colour xtal Metal Detector PC board Length of twin shielded cable, plastic pot stand (approx 150 mm dial, length of steel or aluminium tube (approx 600 mm long, 20 mm dia), length of plastic rod or wood dowel to fit inside pipe (approx 200 mm long), 0.4 mm enamelled wire, aluminium foil, Araldite, box to suit (approx 105 x 125 x 75 mm), three knobs, battery clips, insulation tape, two right-angle brackets. |

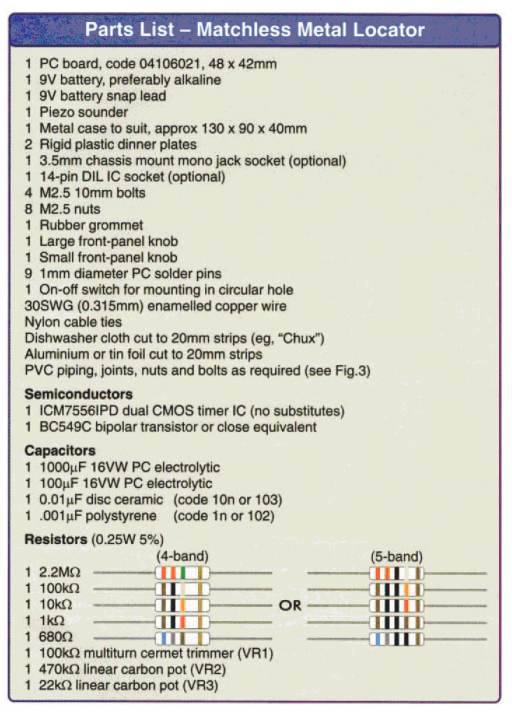

Matchless

Metal Locator

by Thomas Scarborough

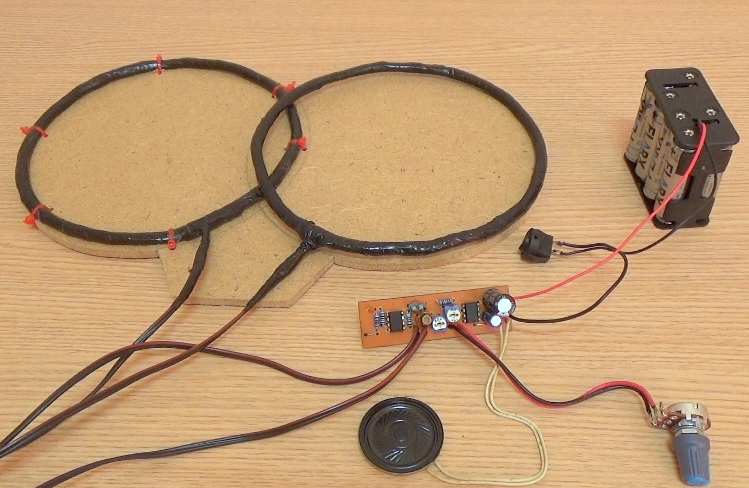

Want to find a fortune? Buried treasure, perhaps? Lost coins on the beach? Or perhaps you fancy earning some pocket money finding other people's valuables. Either way, this project should really interest you. It's an el-cheapo induction balance (IB) metal locator that delivers surprisingly good performance.

An induction balance (IB) metal locator has a good depth of penetration and distinguishes well between ferrous and non-ferrous metals. It is also capable, to a large extent, of rejecting iron and also tin foil This is a boon for anyone who is searching for coins or noble metals.

My aim with this design was to create a 'minimalist' device — one that would work well but without all the bells and whistles of the expensive, commercial designs. I found that it was possible, with just a handful of components, to design a high-quality metal locator.

Simple, but it works

An IB metal locator is usually far more complex than the design shown here.

The reason for the simplicity is that I have dispensed with analogue circuitry, and instead used a digital transmitter and receiver.

As the search coils pass over metal, only digital signals of a certain amplitude break through to a peak detector (IClb). Since these are in the audio range, they are immediately transferred to the piezo sounder or headphones.

On testing the sensitivity of this design in air, with optimal tuning and using a 25mm-diameter brass coin, it gave a clear signal at 150mm, and a 'screaming' signal at 110mm. It was also able to detect a pin at 30mm.

Note that these figures may not apply in the ground,

where depth of penetration will depend largely on the mineralisation

present.

In contrast, the locator is far more reluctant to pick up tin foil. A

tin foil disk of the same size as the brass coin was only detected at

half the distance in air. This rejection of tin foil is due in part to

the metal locator's low frequency, which avoids what is called skin

effect.

Besides this, if the two coils are positioned as described, ferrous

metals (iron) are, to a very large extent, rejected — to such an extent,

in fact, that a 25mm diameter brass coin weighing seven grams looks the

same to the metal locator as a lump of iron weighing 20 times as much.

Large nonferrous objects are detected at half a metre distance and more.

The locator's power consumption is conveniently low. It draws around

10mA, which means that it may be powered off a small 9V battery. If an

alkaline battery is used, this will provide about 48 hours' continuous

use. In my experience, the number of coins that are found on a beach in

an hour or two should easily make up for the cost of batteries!

Finally, while the stability of the locator is not the best, it's by no

means the worst either. Re-tuning is necessary from time to time,

especially in the first few minutes of use. One soon becomes accustomed

to giving the Fine Tune knob an occasional tweak — perhaps with every 40

or 50 sweeps of the search head.

Circuit description

The search head of a typical IB metal locator contains two coils: a

transmitter (Tx) coil and receiver (Rx) coil.

In this case, the Tx coil is driven by a square wave oscillator, which

sets up an alternating magnetic field in the coil. The Rx coil is then

positioned in such a way that it partly overlaps the Tx coil. By

adjusting the amount of overlap, a point can be found where the voltages

in the Rx coil 'null' or cancel out, so that little or no electrical

output is produced. A metal object which enters the field then causes an

imbalance, resulting in a signal.

The transmitter (IC1a) is a standard 555 oscillator configuration, using

one half of the ICM7556IPD dual low power CMOS version of this IC.

Do NOT use the NE556N IC, by the way.

IC1a oscillates at about 700Hz, determined by R/C components around pins

1, 2 and 6. The 680R resistor limits the current passing through the Tx

coil.

The receiver section (IC1b) is preceded by a simple

yet sensitive preamplifier stage, based on Q1, which amplifies the

signal received from the Rx coil. This is fed directly to IC1b, which is

used here as a high-performance sine-square converter. Its input at

pins 8 and 12 is biased by the divider formed by the 10k resistor and

pots VR1-VR3, so that only pulses of a certain amplitude break through

to output pin 9.

There is a point at which, with careful adjustment, the signal is just

breaking through in the form of a crackling sound. When the locator's

output is adjusted to a fast crackle, the presence of metal turns this

into a 'scream'. This is heard from the piezo sounder or through

standard headphones. The 7556 IC allows up to 100mA of output current,

therefore no further amplification is required.

Winding the coils

The one drawback to any IB metal locator design is its need for two

coils, which must be very carefully and rigidly positioned in relation

to one another. Sometimes there's no room even for a fraction-of-a-millimetre

error in positioning these coils. While this particular design makes

things easier than usual, the placement of the coils will still require

some patience. On the other hand, the winding of the coils is relatively

easy. Each coil also includes a electrostatic (Faraday) shield, which

helps to minimise ground effect.

The winding of the (identical) coils is not critical and a little give

and take is permissible.

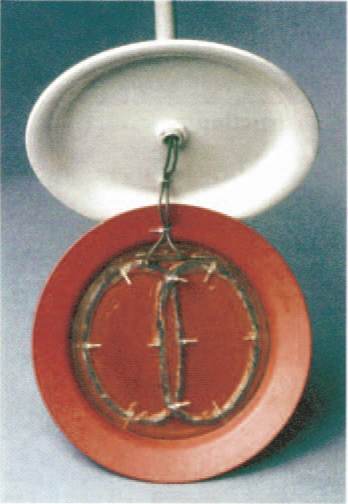

I used 30SWG (0.315mm) enamelled copper wire, winding 70 turns on a

circular former, 120mm in diameter.

I created the former with a sheet of stiff cardboard with 12 pins stuck

through it at a suitable angle (the heads facing slightly outwards). The

coil was wound clockwise around the pins, then temporarily held together

with stubs of insulating tape passed under the coil and pressed together

over the top. The coil may be jumble-wound (that is, you don't have to

wind the turns on side-by-side in neat layers).

Once this has been done, the pins are removed, and a second coil is

wound in the same way. In each case, mark the beginning and end wires.

Each coil is then tightly bound by winding insulating tape around its

entire circumference.

Now we add a Faraday shield to each coil. This is accomplished with some

long, thin strips of aluminium foil. First scrape the enamel off each

coil's end wire. Solder a 100mm length of bare wire to the winding wire,

and twist this around the coil, over the insulating tape. This provides

electrical contact for the Faraday shield.

Beginning at the base of this lead, the foil is wound around the

circumference of the coil, so that no insulating tape is still visible

under the foil but the foil should not complete a full 360°. Leave a

small gap (say 10mm) so that the end of the foil does not meet the start

after having gone most of the way around. Do this with both coils. Each

coil is now again tightly bound with insulating tape around its entire

circumference.

Attach each of the coils to its own length of quality single-core

screened audio cable, with the Faraday shield in each case being

soldered to the screen. Do not use stereo or twin-core microphone wire

to run both leads together; this may cause interference between the

coils.

Gently bend the completed coils until each one is reasonably flat and

circular, with each end wire facing away from you, and to the right of

the beginning wire. Now bend them further until they form lopsided ovals

like capital Ds (see Fig. 2). The backs of the Ds overlap each other

slightly in the centre of the search head. This is the critical part of

the operation, which we shall complete after having constructed the

circuit.

Last of all, wind strips of absorbent cloth around each coil (I used

strips of thin dishwashing cloth such as Chux), using a little

all-purpose glue to keep them in place. Later, when epoxy resin is

poured over the coils, this cloth meshes the coils into the resin.

Construction

The PC board of the Matchless Metal Locator measures 48mm x 42mm, and is

coded 04106021. There are not many components, so it should be easy to

assemble the board using the PC board overlay diagram in Fig. 3.

With the exception of the CMOS IC, component values and types are not

critical. The one critical component is the ICM7556IPD CMOS IC. I also

tried the TS556CN IC in this position — it worked, but not as well.

Begin board assembly by soldering the nine terminal pins, the 14-pin

dual-in-line socket for IC1 and the resistors. Continue with the

capacitors, diodes and Q1.

Once soldering is complete, carefully check the board for any solder

bridges, then use some short lengths of quality screened microphone wire

to attach the piezo sounder, VR2 and VR3, with the screen (or braid)

always being wired to 0V. If you wish, add a socket for headphones in

parallel with or in place of the piezo sounder. Use insulated hook-up

wire to attach the battery and switch S1, keeping the leads short.

Finally, attach the screened cables from the coils, with the screen

again going to 0V, and insert IC1 in the DIL socket. Note that IC1 is

static sensitive, and requires careful handling (discharge your body to

earth before handling).

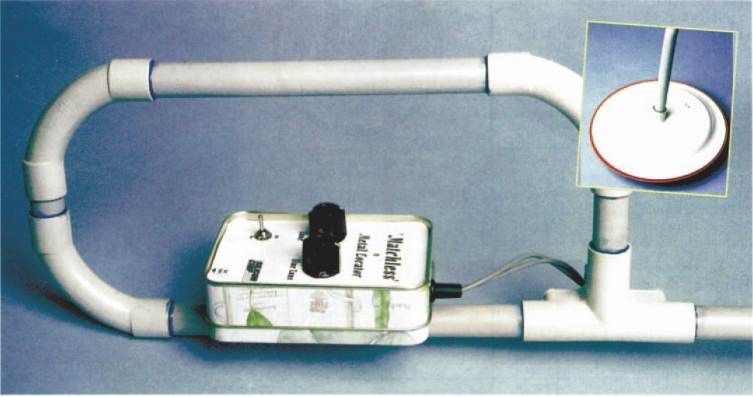

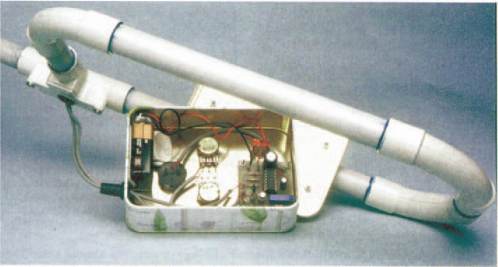

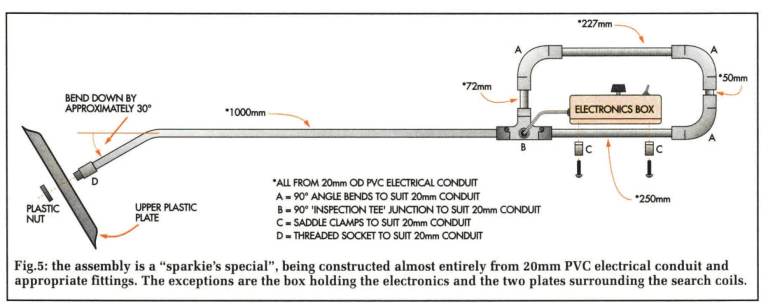

Fig. 5 shows the suggested hardware construction, using PVC piping and

joints. Bend the base of the metal locator's shaft under very hot water

to obtain the angle shown. Alternatively, a swivel joint may be made.

The entire electronics (apart from the search coils) is mounted in a

metal case, ensuring that no part of the underside of the PC board is

touching the case. The adjustment slot for VR1 should be accessible via

a small hole in the case. Mount VR2 and VR3 where quick and easy

adjustment is possible.

A metal case is essential, otherwise the circuit is affected by

electrostatic coupling (or capacitive effects). The metal case is

connected to 0V, through the tab on the copper side of the PC board.

I was unable to obtain a purpose-made metal case in my city (Cape Town),

but found that good quality metal sweet tins were readily available, so

I used one of these. They are also considerably cheaper than similarly

sized electronics enclosures and of course you get the sweets as well!

Setting the coils

A completed PC board is needed before we can 'pot' the coils. These are

potted with epoxy resin in a hard plastic dinner plate, the sort you'd

find in a picnic set. Any plastic plate of suitable size will do, on

condition that it is rigid. (A tip: don't pinch them from the family

picnic set....)

First place the coils on top of one another — ensuring that they are

correctly orientated, with each end wire facing away from you, and to

the right of the beginning wire. Adjust both VR2 and VR3 to their

midpoint. Adjust VR1 to about 90kQ. Then attach a 9V battery and switch

on. The circuit will most likely be screaming; that is, beeping loudly

and continuously. Now slowly move the coils apart. When they are

somewhere past the halfway point, the headphones will fall silent. This

is where the voltages in the Rx coil 'null'. Continue to move the coils

apart. At a precise point just before the coils no longer overlap at all

— the headphones will begin to scream again (there may or may not be a

low-level beep just before this).

It is at this precise point, and not a fraction of a millimetre either

way, that the coils need to be set.

Take an indelible marker pen and mark out holes in the lower plate

around both coils. These holes are used to pass cable ties through, to

hold the coils tightly to the plate. Also use a cable tie to hold the

audio cables to the plate. Use some Blu-tak to tightly seal the holes

underneath the plate before pouring in the resin — epoxy resin can be

very 'runny' and sticks faster than many glues.

Also at this point carefully bend the coils at the centre of the plate

until you reach the exact balance at which there is neither silence nor

screaming in the piezo sounder/headphones, but just a crackle. A little

drift should not matter at this point.

Now you are ready to mix and pour the resin. Use a modest amount of

catalyst, so that there will be not too much heat and shrinkage in the

resin. Pour the resin over the cloth which surrounds the coils, so as to

soak it, and keep on pouring at least until the entire bottom of the

plate is covered with resin.

The circuit may no longer function correctly at this point until the

resin has hardened, so make no more adjustments at this stage, but

switch the circuit off and leave it for 24 hours or so.

I potted two sets of coils (that is, two complete search heads). The

first worked perfectly, precisely as I had set it in the plate. The

second contracted slightly as the resin set, so that no settings of VR2

or VR3 would produce a tone in the headphones. However, this is where

the design of the Matchless Metal Locator shows its flexibility. By

turning VR1 clockwise, the circuit was again functioning normally when

VR2 and VR3 were set to their midpoint.

How to use it

Keep the search head away from all metal — and "noisy" computer

equipment — and switch on. Adjust potentiometers VR2 (Tune) and VR3

(Fine Tune) to their mid-points. Then adjust VR1 with a screwdriver or

plastic alignment tool until the metal locator is just at the point

where a crackle is heard, between silence and a scream (or between a

low-level hum and a scream). Use the tune and fine-tune knobs for any

further tuning.

A fast crackling sound produces the best results. Move a coin over the

search head and the piezo sounder should scream.

In actual use, the adjustment of the metal locator will be affected by

the mineralisation of the ground you are searching, as well as

temperature and voltage variations. So as mentioned earlier,

readjustments to VR3 and VR2 are inevitable from time to time.

That's really all there is to it.

Here is a Metal

Detector using a CD4011 IC:

The oscillator is built with NAND N1 and a ceramic filter of frequency 470kHz. The second oscillator is with N3 and a LC combination. The frequency

of this oscillator. is adjusted in such way that will produce an audible oscillation of

both frequencies.

Thru N4, the signal from the variable oscillator. is amplified. If the sensor coil L1

is closer to a metal object then it will modify the auto-induction of the coil,

the oscillator is unbalanced and the sound will modify.

Another Simple Metal Detector Circuit:

This circuit is identical

to Fig 7 above and the Metal Detector

in 200 Transistor Circuits

Another Simple Metal Detector Circuit:

SIMPLE METAL DETECTOR USING A TAPPED COIL

CD 4093 IC Metal Detector

This circuit uses a single coil and nine components to make a particularly

OP AMP METAL DETECTOR

This circuit has

been tested on 23-12-2013. It produces an oscillation at approx 530kHz.

The sensitivity is the same as all the other single transistor circuits, but it

uses a tapped

coil to provide the feedback and this eliminates two components.

sensitive low-cost metal locator. It works on the principle of a beat frequency

oscillator (BFO). The circuit incorporates two oscillators, both operating at

about 40kHz. The first, IC1a, is a standard CMOS oscillator with its frequency

adjustable via VR1. The frequency of the second, IC1b, is highly dependent

on the inductance of coil L1, so that its frequency shifts in the presence of

metal. L1 is 70 turns of 0.315mm enamelled copper wire wound on a 120mm

diameter former. The Faraday shield is made of aluminium foil, which is wound